Surface coating and assembly

In the electrification industry, it is crucial to protect precious metals from oxidation or poor connections. Eboss relies on a strong network of sub-suppliers who apply the necessary surface treatments to components. Tinplating or silverplating copper and brass parts is common practice. Eboss also operates an in-house line for applying silver coatings. New innovations are underway to enable partial silver coating of parts, helping to reduce costs.

Our sister company, AntiCorr AB, features a powder coating line where steel and aluminium parts are typically coated with polyester. Thanks to our wide network of sub-suppliers, we are also able to provide anodizing, zinc coatings, and various other types of finishes.

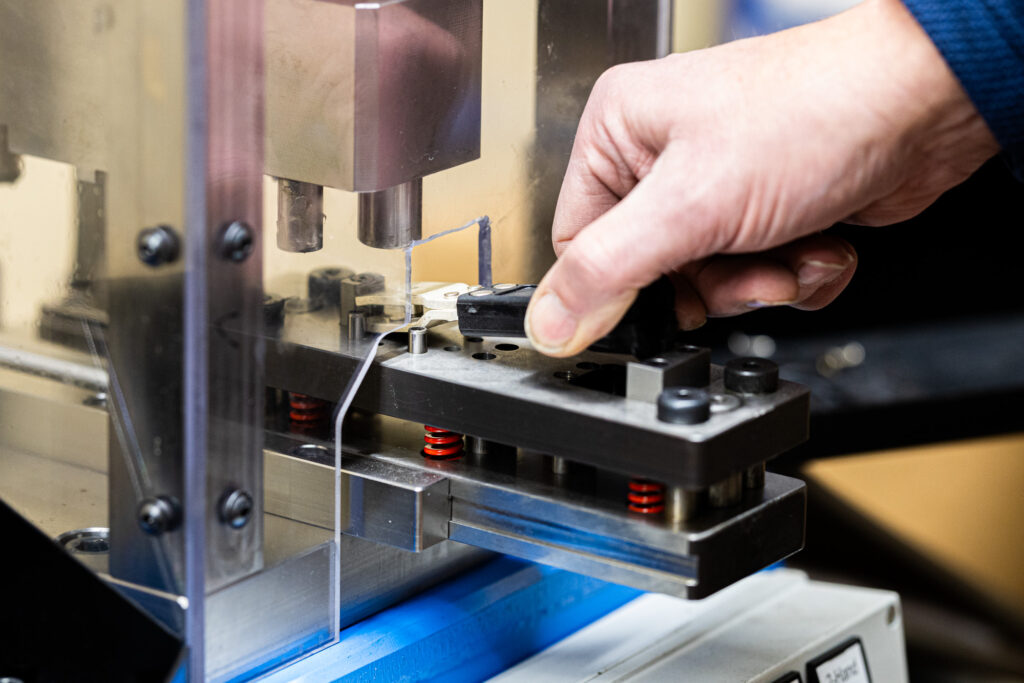

Assemblies

As we often manufacture several components for inbound assemblies, it is logical to also manage procured components to create complete assembled units. This approach simplifies ordering for end-users, allowing them to purchase a single part rather than multiple individual components. Eboss designs and manufactures its own assembly gauges and controls to ensure safe and functional products for customers. Bolts, nuts, rivets, plastic parts, and electrical equipment are among the various items sourced from approved suppliers.

The result is a reliable and cost-effective product.

Would you like to give us a try?